-

Road

-

MTB

- E-Bike

-

BMX

- City

-

Accessories

-

Riders Gear

-

Ladies

- Kids

-

Streetwear

- Triathlon

-

Brands

1

- 100%

A

- A2z

- Absoluteblack

- Abus

- Acros

- Add one

- Addbike

- Adidas

- Adidas terrex

- Agu

- Aivee

- Ale

- All mountain style

- All-city bikes

- Alligator

- Alpina

- Alpinestars

- Altra

- Altura

- Amphora

- Animal bikes

- Animoz

- Answer products

- Aqua2go

- Aquaman

- Arena

- Ashima

- Asics

- Aso

- Ass savers

- Assos

- Asterion

- Avian bmx

- Avid

- Axa

- Azr

- Challenge

- Chase bicycles

- Chris king

- Chromag

- Chrome

- Ciari

- Ciclosport

- Cinelli

- Clarks standard

- Clif bar

- Cobra bikes

- Colting

- Commencal

- Compex

- Compressport

- Continental

- Craft

- Crane bell co.

- Crankbrothers

- Creme

- Croozer

- Crosscall

- Cube

- Cube acid

- Cube rfr

- Cult

- Cushcore

- Cybex

- Cyclingceramic

- Cyclus tools

D

- Dainese

- Dakine

- Dare 2b

- Dare2tri

- Dartmoor

- Deboer

- Deda

- Deda elementi wheels

- Deuter

- Dexshell

- Dhb

- Diamant

- Dm3

- Dmr

- Dt swiss

- Dugast

- Dvo

- Dynaplug

G

- G-form

- Galfer

- Garmin

- Genuine innovations

- Ghost

- Giro

- Gonso

- Gorewear

- Granite design

- Gripgrab

- Gt bicycles

H

- Haibike

- Hamax

- Hammerhead

- Hayes

- Head

- Hebie

- Hed

- Hexlox

- Hiplok

- Hjc

- Hope

- Ht components

- Hutchinson

- Huub

- Hydrapak

- Maxxis

- Mb wear

- Melon optics

- Merrell

- Met

- Mh cover

- Miche

- Michelin

- Microshift

- Milkit

- Miranda

- Mizuno

- Mongoose

- Monkeylink

- Morgaw

- Motion ride

- Moto

- Motorex

- Mottez

- Mrp

- Msc bikes

- Muc-off

N

- Neat flow

- New balance

- Newmen

- Newton running

- No-flats

- North shore billet

- Northwave

- Notubes

- Now8

- Ns bikes

- Nukeproof

- Nutcase

O

- O'neal

- O.symetric

- Oakley

- Odi

- Odlo

- Odyssey

- Oneup components

- Onyx

- Orange

- Orbea

- Ortler

- Ortlieb

- Osprey

- Oury

- Rant

- Red cycling products

- Renthal

- Respro

- Restrap

- Reverse components

- Revoloop

- Reynolds

- Rh+

- Ride concepts

- Ridley

- Ritchey

- Riva

- Rocday

- Rockshox

- Roeckl

- Rondo

- Roto

- Rotor

- Rrp

- Rudy project

S

- S'cool

- Sailfish

- Salming

- Salt

- Saltplus

- Santini sms

- Sapim

- Saris

- Saucony

- Sb3

- Schwalbe

- Scicon

- Scope

- Sdg

- Se bikes

- Se racing

- Sea sucker

- Sella italia

- Selle italia

- Selle royal

- Selle san marco

- Sendhit

- Serious

- Shapeheart

- Shimano

- Sidi

- Sigma

- Silca

- Silva

- Sixpack

- Sixs

- Sixsixone 661

- Skean

- Skf

- Skins

- Sks germany

- Slicy

- Smith

- Smp

- Sock guy

- Spank

- Spanninga

- Specialites ta

- Speedo

- Spirgrips

- Spiuk

- Sportful

- Sportourer

- Squirt lube

- Sr suntour

- Sram

- Stages cycling

- Stranger

- Strobmx

- Stronglight

- Sun ringlÉ

- Sunrace

- Suomy

- Supacaz

- Supernova

- Supertour

- Sweet protection

- Swissstop

- Thickslick

- Thomson

- Thule

- Ti-springs.com

- Tigra sport

- Time

- Tioga

- Title

- Tnt bicycles

- Topeak

- Topo athletic

- Trail gator

- Transition bikes

- Troy lee designs

- Trp

- Truvativ

- Tsg

- Tubolito

- Tubus

- Tucano urbano

- Tufo

- Tune

- Tyr

V

- Vans

- Var

- Vaude

- Velco

- Velotoze

- Velox

- Vermont

- Viper

- Vision

- Vittoria

- Vitus

- Vojo

- Votec

- Vredestein

- Vsf fahrradmanufaktur

LEATT - Technology

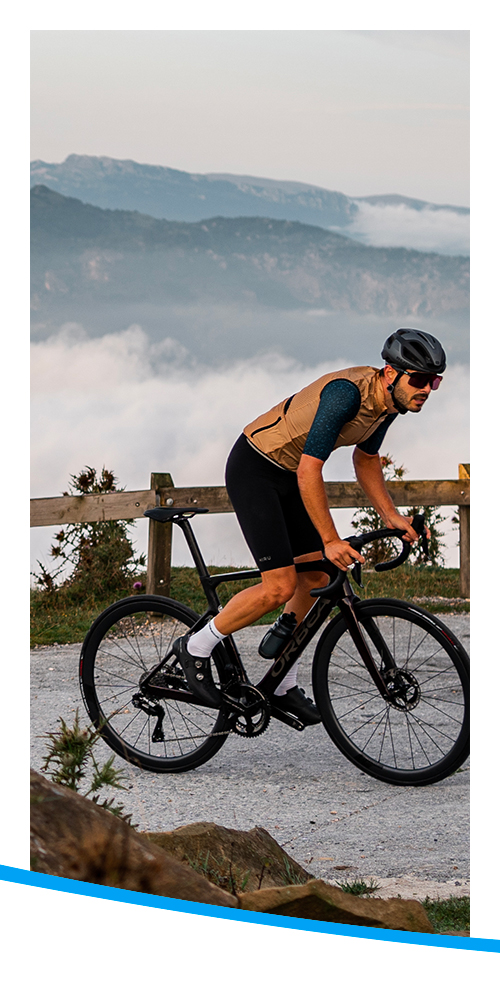

Welcome to the Leatt Thrill!

Leatt was created in the early 2000s. Ever since then, the company has endeavoured to make the most extreme disciplines as safe as possible without compromising on performance or reducing that burst of adrenaline you get when working to shave a few seconds or even a thousandth of a second off your time. Leatt’s range of helmets, body armour suits, neck braces, elbow pads and knee guards, as well as their constantly evolving clothes line will give you the confidence you need to ride faster, further and with more power. Go beyond your limits and do it safely!

2001 South-African neurosurgeon and a keen Motocross enthusiast, Chris Leatt, provided medical services at international competitions. One day, Leatt witnessed the death of a pilot during an Enduro Motorcycling competition and he was powerless to prevent it. This event affected him profoundly occurring right at the same time when his 4-year old son was just learning to cycle. And thus, he decided to build a neck brace prototype that would prevent such an accident from ever happening again.

2004 Dr Leatt spent three years on research and development before his concept materialised. He then launched his first Leatt neck brace in South Africa.

2006 At EICMA - the Milan motorcycle show -, the product was noticed by influential stakeholders in the industry, namely BMW Motorrad. The product was then mass-produced. The finalised version of the neck brace was presented at the Cologne International Motorcycle Conference and was sold on a large scale.

2007 The product was immediately very successful: the Leatt neck brace made the cover of Racer-X – an expert magazine – who named it product of the year. Motocross Action gave it a score of 5/5 and famous pilot, David Bailey, who became a paraplegic following a fall, sings its praises in a video. These accolades made demand shoot through the roof.

2008 Chris Leatt then created the Leatt Lab research laboratory to do even more to protect pilots and add more fuel to his ambitions. This entity is renowned worldwide for its high quality tests and protocols.

2009Leatt's continuous efforts to improve the product were recognised numerous times at international trade shows and by the trade press (Transworld Motocross, Racer-X, Motocross Action, Freeride Magazine, Dirt Bike Magazine, etc.)

2010 After his unequivocal success in the Motocross world, Leatt decided to throw himself into cyclist protective wear with DBX, the first neck brace specially developed for MTB. This product received the BikeExpo Award (Safety Equipment category). This item was adopted by Sam Hill upon his return to competitions following an injury. Sam Hill then went on to win his third DH World Champion title. That same year, motorcycle pilot Ryan Dungey won the Supercross Championship wearing the DBX neck brace.

2012Leatt then used his expertise in pilot safety to extend his range and create the Pro Lite vest, which, thanks to its unparalleled level of protection, then won the prestigious product of the year title, awarded by Transworld Motocross Magazine.

2013Leatt launched new products: the Fusion 2.0 Junior (now 2.5), a model specially developed for children, which includes a neck brace and a chest and neck protection, and the neck brace 5.5 (to replace the GPX 6.5 Carbon), a new generation of neck braces with even better performance. That same year, Cyril Despres won his fifth Dakar rally while wearing Leatt protections.

2016The brand tirelessly continued to innovate. That year, it launched the Leatt DBX 5.0 helmet and the DBX Enduro Lite WP 2.0 hydration system, both of which won a Eurobike Award. Also, Racer-X magazine readers ranked Leatt top for neck braces.

2017In 2017, Leatt was once again recognised for the neck brace 3.5, which won awards at the Eurobike and Interbike trade shows.

Technology

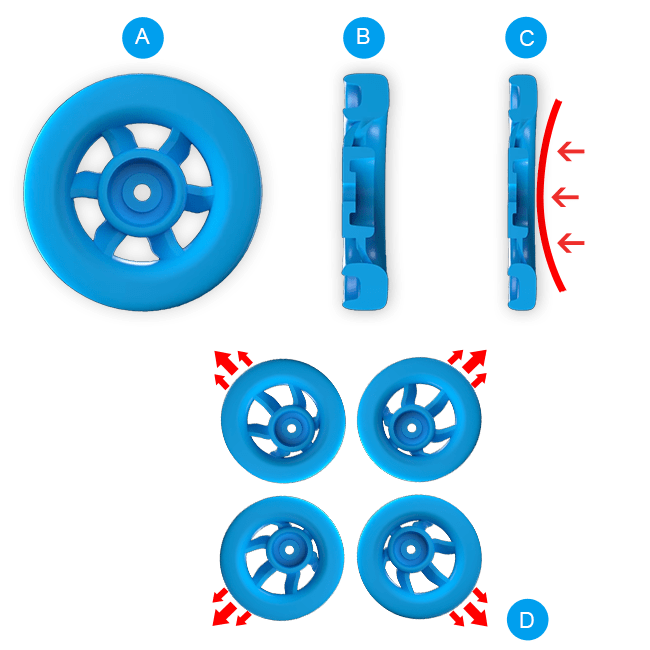

turbine 360°

The world-renowned 360° Turbine technology was developed in the Leatt Lab research laboratory and can be found on all Leatt helmets (exclusively). The idea is not only to reduce linear impact in the event of a head-on collision but also to reduce rotation in the case of a high-speed fall.

In concrete terms, the 360° Turbine technology is based on small turbines a the size of a two euro coin, distributed strategically inside the helmet and inserted into the EPS internal shell. These turbines are made of a material that absorbs impact effectively b by hardening instantaneously c in the event of impact. They can also move in all directions.d. The result is that these shock absorbers reduce the impact energy by 30% and the rotational force, caused by oblique impact, by 40% to then reduce the risk of concussion should the pilot fall on their head.

see the whole range

Technology

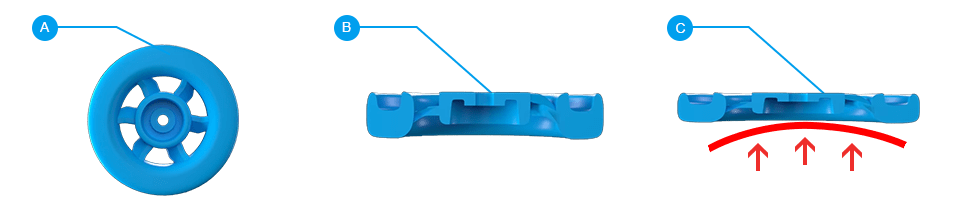

3DF

South African brand Leatt used its unique and renowned expertise, gained from its research laboratory and tests, to develop its own pilot protection technology, 3DF. This material consists of several layers of memory foam that hardens immediately upon impact A and guarantees very effective energy dispersion B. The material then resumes its original shape and namely its high level of softness to provide you with total comfort and outstanding freedom of movement. Furthermore, 3DF is evenly perforated to ensure good ventilation. 3DF can be found in Leatt’s top-end protective equipment: vests, elbow pads, knee guards, and shin guards.

see the whole rangejackets

dbx 5.0

Anti-abrasion lining at the shoulders to limit the effects of wearing a backpack and improve stability. This feature can also be found at the elbows for increased protection in the event of a fall.

Two large zipped openings on the front panel for tailored ventilation.

One includes a cleaning cloth to clean goggles and glasses.

Handle with a velcro adjustment band to avoid air or water entering the sleeves

Watertight zipper closure to avoid any infiltration of water and keep the entire jacket waterproof.

The bottom of the hood has a gusseted shape, making it easy to move while both eliminating any risk of friction and irritation and preventing air from rushing in.

Zipped front pocket on the left arm for your Bike-Park pass or other.

Hooks keep the hood elastics flush against the jacket, even during the worst jolts.

Over the last few years, Leatt went beyond pilot safety and developed a full range of clothing that is both sophisticated and technical. This includes jackets that have been specially developed to overcome to MTB issues.

DBX 5.0 is THE latest model that you absolutely need to face all weather conditions. It is made of a waterproof breathable material with some of the highest values in the market (30,000 mm / 23,000 MVTR). It is fitted with large zipped openings to adjust the ventilation as required and its four-way stretch material gives it the perfect fit and guarantees total freedom of movement.

It also includes numerous high quality details, starting with the magnet hood system. This allows the hood to stay perfectly in place both when you fold it down behind your jacket and when you position it over your helmet (only compatible with Leatt helmets). Reinforced anti-slip inserts have also been fitted at the shoulders to ensure your backpack stays in the right position, even during your toughest rides.

see the whole range