-

Road

-

MTB

- E-Bike

-

BMX

- City

-

Accessories

-

Riders Gear

-

Ladies

- Kids

-

Streetwear

- Triathlon

-

Brands

1

- 100%

A

- A2z

- Absoluteblack

- Abus

- Acros

- Add one

- Addbike

- Adidas

- Adidas terrex

- Agu

- Aivee

- Ale

- All mountain style

- All-city bikes

- Alligator

- Alpina

- Alpinestars

- Altra

- Altura

- Amphora

- Animal bikes

- Animoz

- Answer products

- Aqua2go

- Aquaman

- Arena

- Ashima

- Asics

- Aso

- Ass savers

- Assos

- Asterion

- Avian bmx

- Avid

- Axa

- Azr

- Challenge

- Chase bicycles

- Chris king

- Chromag

- Chrome

- Ciari

- Ciclosport

- Cinelli

- Clarks standard

- Clif bar

- Cobra bikes

- Colting

- Commencal

- Compex

- Compressport

- Continental

- Craft

- Crane bell co.

- Crankbrothers

- Creme

- Croozer

- Crosscall

- Cube

- Cube acid

- Cube rfr

- Cult

- Cushcore

- Cybex

- Cyclingceramic

- Cyclus tools

D

- Dainese

- Dakine

- Dare 2b

- Dare2tri

- Dartmoor

- Deboer

- Deda

- Deda elementi wheels

- Deuter

- Dexshell

- Dhb

- Diamant

- Dm3

- Dmr

- Dt swiss

- Dugast

- Dvo

- Dynaplug

G

- G-form

- Galfer

- Garmin

- Genuine innovations

- Ghost

- Giro

- Gonso

- Gorewear

- Granite design

- Gripgrab

- Gt bicycles

H

- Haibike

- Hamax

- Hammerhead

- Hayes

- Head

- Hebie

- Hed

- Hexlox

- Hiplok

- Hjc

- Hope

- Ht components

- Hutchinson

- Huub

- Hydrapak

- Maxxis

- Mb wear

- Melon optics

- Merrell

- Met

- Mh cover

- Miche

- Michelin

- Microshift

- Milkit

- Miranda

- Mizuno

- Mongoose

- Monkeylink

- Morgaw

- Motion ride

- Moto

- Motorex

- Mottez

- Mrp

- Msc bikes

- Muc-off

N

- Neat flow

- New balance

- Newmen

- Newton running

- No-flats

- North shore billet

- Northwave

- Notubes

- Now8

- Ns bikes

- Nukeproof

- Nutcase

O

- O'neal

- O.symetric

- Oakley

- Odi

- Odlo

- Odyssey

- Oneup components

- Onyx

- Orange

- Orbea

- Ortler

- Ortlieb

- Osprey

- Oury

- Rant

- Red cycling products

- Renthal

- Respro

- Restrap

- Reverse components

- Revoloop

- Reynolds

- Rh+

- Ride concepts

- Ridley

- Ritchey

- Riva

- Rocday

- Rockshox

- Roeckl

- Rondo

- Roto

- Rotor

- Rrp

- Rudy project

S

- S'cool

- Sailfish

- Salming

- Salt

- Saltplus

- Santini sms

- Sapim

- Saris

- Saucony

- Sb3

- Schwalbe

- Scicon

- Scope

- Sdg

- Se bikes

- Se racing

- Sea sucker

- Sella italia

- Selle italia

- Selle royal

- Selle san marco

- Sendhit

- Serious

- Shapeheart

- Shimano

- Sidi

- Sigma

- Silca

- Silva

- Sixpack

- Sixs

- Sixsixone 661

- Skean

- Skf

- Skins

- Sks germany

- Slicy

- Smith

- Smp

- Sock guy

- Spank

- Spanninga

- Specialites ta

- Speedo

- Spirgrips

- Spiuk

- Sportful

- Sportourer

- Squirt lube

- Sr suntour

- Sram

- Stages cycling

- Stranger

- Strobmx

- Stronglight

- Sun ringlÉ

- Sunrace

- Suomy

- Supacaz

- Supernova

- Supertour

- Sweet protection

- Swissstop

- Thickslick

- Thomson

- Thule

- Ti-springs.com

- Tigra sport

- Time

- Tioga

- Title

- Tnt bicycles

- Topeak

- Topo athletic

- Trail gator

- Transition bikes

- Troy lee designs

- Trp

- Truvativ

- Tsg

- Tubolito

- Tubus

- Tucano urbano

- Tufo

- Tune

- Tyr

V

- Vans

- Var

- Vaude

- Velco

- Velotoze

- Velox

- Vermont

- Viper

- Vision

- Vittoria

- Vitus

- Vojo

- Votec

- Vredestein

- Vsf fahrradmanufaktur

CUBE - Technology

Cube Technology

HYBRID TECHNOLOGY

Over the last few years, above all, Cube has mastered the integration of motorisation. The Cube MTBs, hybrid bikes, trekking bikes and city bikes are fitted with engines and batteries by Bosch, an industry leader. They are also renowned for their particularly striking aesthetics and integration that creates an unbelievably streamlined look and still guarantees pedalling with an extremely natural feel.

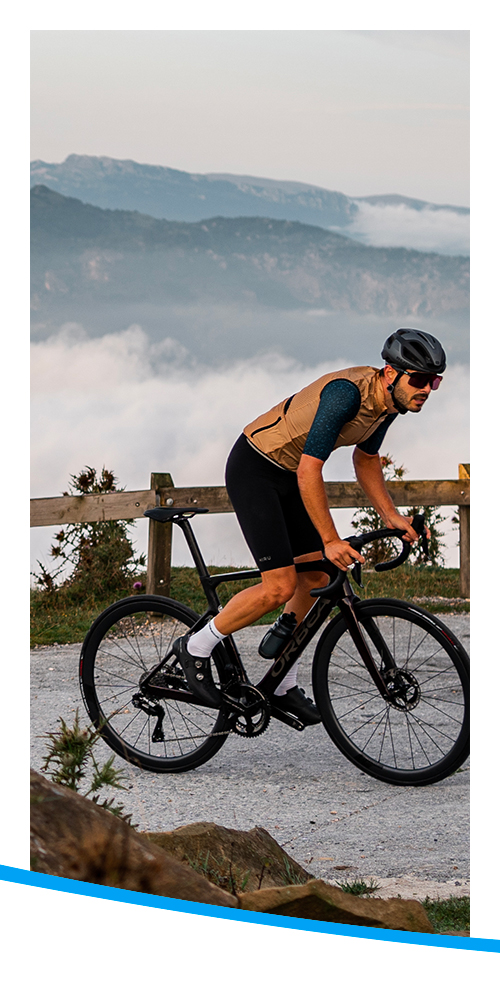

For Road cycling, Cube has been working closely with Fazua, the engine unit brand that provides solutions to all issues related to size, weight or too much pedalling resistance above the power assistance threshold.

-

Stereo Hybrid 160 Action Team -

AGREE HYBRID C:62 SLT Disc

Carbon Technology

Thanks to the C:68 technology, CUBE has managed to reduce its frame thickness by 25% and significantly decrease the frame weight. These frames are 68% carbon and 32% resin with added nanoparticles. Their manufacturing process makes them both stiffer and more compliant. The German brand has now gone even further and evolved this technology to the next level. C:68 frames were formed of homogeneous layers of carbon but the new models are now made of 6 different types of fibre, all orientated according to load. And that is the C:68X technology! The result? Safer, stiffer frames with better aerodynamic properties and that are also lighter and more comfortable. And all of this is thanks to the meticulous selection of materials and their targeted distribution.

Innovative Carbon

A C:68 frame combines this carbon fibre with the Advanced Twin Mold manufacturing process to minimise imprecise overlaps by accurately fitting the individual carbon layers’ sensitive overlap regions during the monocoque building process. The result is a frame with no superfluous weight and incredible performance.

C:62 - both light and robust

The high modulus fibres make the C:62 frames extremely light and stiff. Finely dispersed nanoparticles are integrated in the resin that bonds the two carbon layers. These very small particles increase the durability of the frame, which is also less sensitive and more resistant to external force. This combination of nanoresin particles and high modulus fibres (with a fibre content of 62%) is what makes a C:62 stand out from a classic carbon frame. Like the C:68 frames, the C:62 frames have been manufactured using the Advanced Twin Mold process to reduce excess thickness in the layers of material.

ALUMINIUM TECHNOLOGY

7005 High Performance aluminium is designed for top-end use. The special alloy technique and heat treatment create greater rigidity and reduced weight. Greater strength is obtained when the special alloy and hardening heat treatment are combined. Triple or even quadruple butting of raw aluminium means that a minimal quantity of material can be used and the thickness of the wall can be adjusted according to the load. The Superlite aluminium frame with high resistance and heat treatment is rigid, corrosion-resistant and strong. The double butted tubes and thin wall provide outstanding elongation and rigidity, thanks to the patented Advanced Mechanical Forming process that avoids tedious and complex welding procedures. The result? An aluminium frame that is both lighter and stronger.

A UNIQUE LABORATORY

To ensure a higher standard of quality, every Cube model is subject to several tests in the brand's internal laboratory.

-

Complete Bikes

This means that all bikes are tested on a roller drum test rig with added weights on the handlebar, saddle and pedals to simulate the weight of a cyclist and their potential luggage. The drum rotates to simulate road surface bumps and, overall, each bike travels several hundred kilometres and has to overcome 1.5 million obstacles.

-

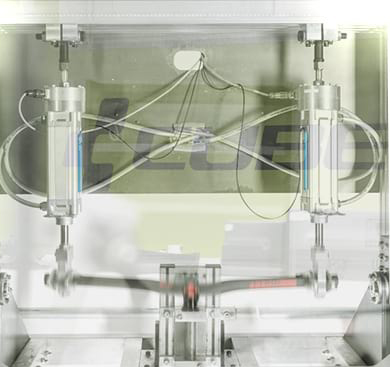

Stem and Seatpost

Each bike's handlebar, stem and seatpost must be 100% reliable and durable. This is why each component is tested twice: once during production and again during Cube's laboratory testing processes.

-

Braking Systems

Whatever the type of bike, the engineers also test the braking systems in all weather conditions and over more than 3,000 cycles to guarantee flawless braking, stability, durability and resistance to wear and tear.

-

Frame and Cranks

For Road bikes, the tests replicate the strong force that the frame and cranks are subject to during a sprint and strong force is applied to the pedals for over 10,000 cycles.

-

Head Tube

For MTBs, the head tube is a particularly vulnerable area due to the large loads transmitted by the suspension fork, which are passed directly through it. Therefore, this type of load is tested intensely on a specific machine that is designed exclusively for this purpose. A realistic load is applied to the fork in order to simulate braking, jumps and other obstacles. Overall, the head tube has to endure 50,000 cycles of this kind without damage before it can be released for production.